"The LH 96 works extremely well.. We do hundreds of tissues a day and we couldn't do it by hand"

-- Senior Research Scientist,Large Pharmaceutical Company

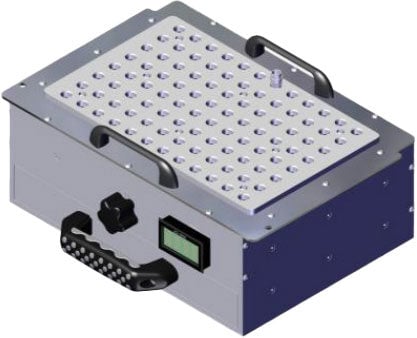

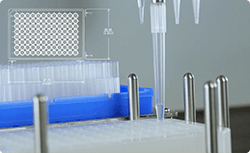

The LH 96 Automated Workstation empowers researchers to focus more on their scientific pursuits and achieve meaningful breakthroughs in their respective fields.

Onboard Dilution Automate precise dilution of samples directly within the system to streamline workflows and ensure accuracy and consistency.

Sample Arm Avoid contamination or loss of samples, while streamlining precision sample handling by automating the transfer of tubes and vials between stations.

Reagent Addition Precisely dispense specified volumes to samples, optimizing consistency and efficiency in laboratory protocols.

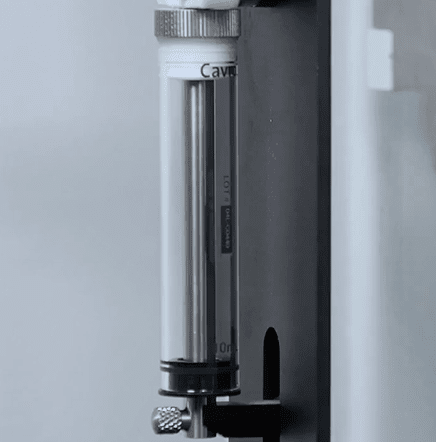

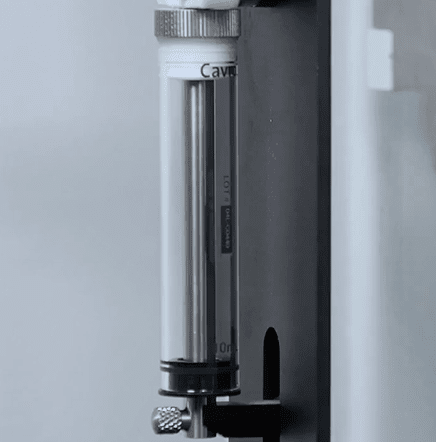

Homogenization Customize homogenization with adjustable speeds, unique probe movements, and power, ensuring thorough and consistent sample processing and sample integrity.

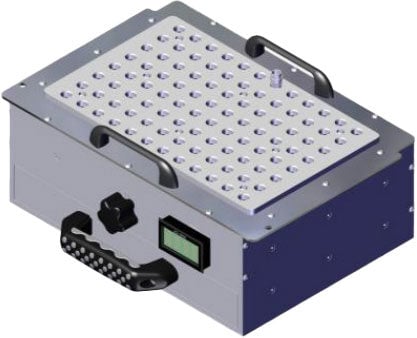

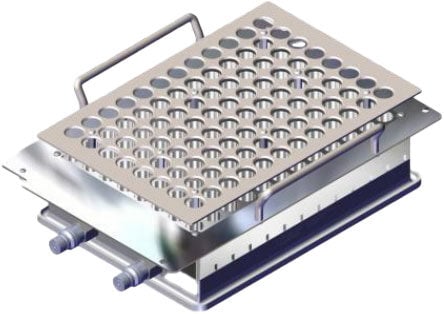

Active Cooling System Circulate glycol coolant at a consistent 4°C with an external heat exchanger, efficiently cooling 2ml, 5ml, 14/15ml, and 50ml tubes.

Passive Cooling Rack Maintain 2ml, 5ml, 14/15ml, and 50ml tubes at or below 4°C for 30-45 minutes at room temperature, with an insulated drawer and temperature readout.

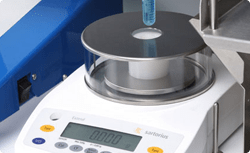

Integrated Scale Automate precise sample measurements with an analytical balance readability to 1 mg, ensuring data logging of sample weights for accurate and efficient tracking within the specific requirements of your application

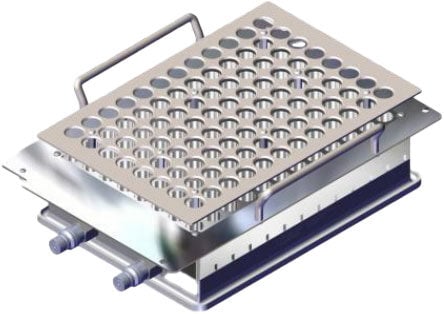

Reformatting Simplify sample reformatting by automatically adjusting sample containers and configurations, enhancing workflow flexibility and efficiency.

Onboard Dilution Automate precise dilution of samples directly within the system to streamline workflows and ensure accuracy and consistency.

Sample Arm Avoid contamination or loss of samples, while streamlining precision sample handling by automating the transfer of tubes and vials between stations.

Reagent Addition Precisely dispense specified volumes to samples, optimizing consistency and efficiency in laboratory protocols.

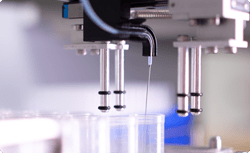

Homogenization Customize homogenization with adjustable speeds, unique probe movements, and power, ensuring thorough and consistent sample processing and sample integrity.

Integrated Scale Automate precise sample measurements with an analytical balance readability to 1 mg, ensuring data logging of sample weights for accurate and efficient tracking within the specific requirements of your application

Reformatting Simplify sample reformatting by automatically adjusting sample containers and configurations, enhancing workflow flexibility and efficiency.

Active Cooling System Circulate glycol coolant at a consistent 4°C with an external heat exchanger, efficiently cooling 2ml, 5ml, 14/15ml, and 50ml tubes.

Passive Cooling Rack Maintain 2ml, 5ml, 14/15ml, and 50ml tubes at or below 4°C for 30-45 minutes at room temperature, with an insulated drawer and temperature readout.

Your All-In-One

Start to finish sample prep – from sample tubes to well-plate. The LH 96 combines automated homogenization, liquid handling, and well plate reformatting of final homogenates.

An integrated scale provides precise measurements within the required range of your application. Proper sample handling is critical to avoid contamination or loss of samples during weighing.

The onboard liquid addition capabilities allow for sample dilution and buffer addition. Dilutions can be achieved at constant volume or by a weight/volume ratio, supporting multiple modes of operation.

Rotor-stator homogenization is utilized to generate sample homogenates that are consistent and reproducible from batch to batch. The ability to generate high-quality homogenates is critical to obtain representative and reliable results during subsequent downstream analyses.

The ability to reformat the homogenates into a well-plate optimizes the entire sample preparation process, minimizing errors, sample mishandling, and contamination risk - operators are propelled into the next step of their workflow.

Automated homogenization improves efficiency, reproducibility, and the quality of sample preparations. It enables researchers to obtain more reliable and consistent results while reducing the time and effort required for sample processing.

Overall, automated homogenization improves efficiency, reproducibility, and the quality of sample preparations. It enables researchers to obtain more reliable and consistent results while reducing the time and effort required for sample processing.

Time & Labor Savings: Automated homogenization eliminates the need for manual grinding or blending of samples, saving significant time and reducing labor-intensive efforts. This allows researchers to process a larger number of samples in a shorter period, increasing productivity and throughput.

Consistency & Reproducibility: Automation ensures a high level of consistency and reproducibility in sample preparation. By following predefined protocols and parameters, automated homogenization produces uniform and consistent sample preparations, reducing the variability that can arise from manual techniques.

Standardization: Automated sample preparation enables standardization across multiple experiments and laboratories. By utilizing the same homogenization settings and methods, researchers can achieve consistent results and compare data across different studies or research groups.

Improved Sample Quality: Automated homogenization can help achieve better sample quality by providing efficient and effective sample disruption and homogenization. This is particularly important for applications such as genomics, proteomics, and metabolomics, where the quality of the starting material can significantly impact the accuracy and reliability of downstream analyses.

Reduce Cross-Contamination: Automation minimizes the risk of contamination and cross-contamination during sample preparation. Closed systems and disposable or autoclavable components prevent sample carryover and reduce the chances of introducing external contaminants, ensuring the integrity of the samples.

Increase Worfkflow Efficiency: Integrating automated sample preparation into laboratory workflows streamlines the overall experimental process. By automating time-consuming and repetitive tasks, researchers can allocate their time and skills to more complex and intellectually demanding activities, accelerating the pace of scientific discoveries.

Data Integrity: Automated sample preparation systems often include software that allows for data tracking, documentation, and traceability. This ensures accurate recording of the sample preparation parameters, facilitating data analysis, and maintaining compliance with regulatory requirements.

Enhanced Safety: Automated homogenization reduces the risk of operator exposure to hazardous or infectious materials. It minimizes the need for manual handling of samples, thereby improving safety and reducing the potential for accidents or injuries.

"The LH 96 works extremely well.. We do hundreds of tissues a day and we couldn't do it by hand"

-- Senior Research Scientist,"The LH 96 does the entire front end of our sample prep.

We can

just walk away while it works. It's amazing."

"With the LH 96, we can process 200 samples

in two days or less, instead

of three."

We offer all customers hands-on application and protocol support during any automation instrument placement. It’s in our DNA. Our team of scientists and application engineers has many years of experience combined to ensure that you are up and running quickly and efficiently.

Let's redefine what's possible in your lab with the Omni LH 96, where cutting-edge technology meets practical application.

Get in touch

935 Cobb Place Blvd